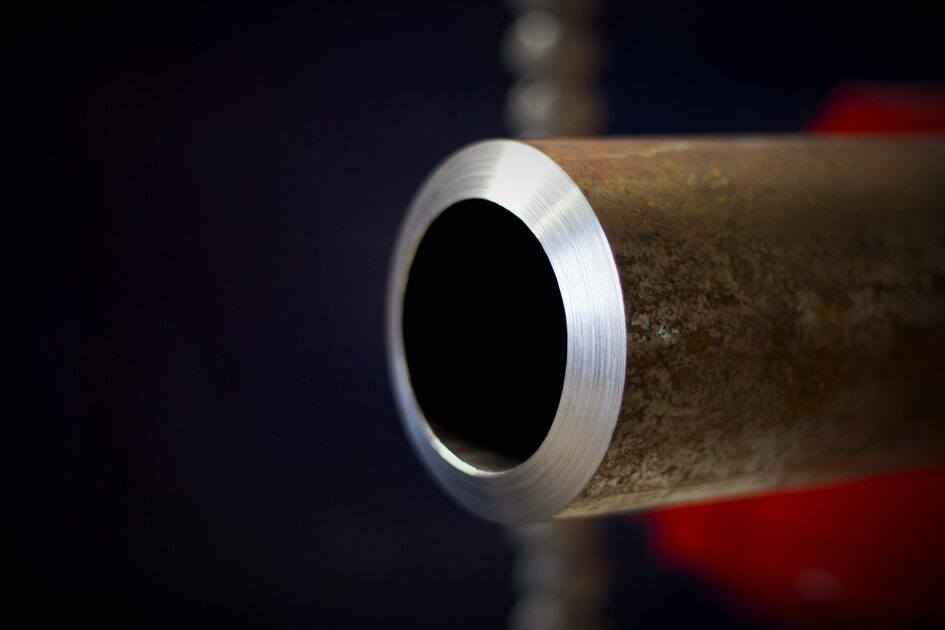

Accurate Beveling for Superior Connections

Beveling is a critical step in preparing pipes and materials for welding or assembly. It ensures precise angles and smooth edges, creating a perfect fit for joints and improving structural integrity. At M-Davit Consulting, our advanced beveling techniques cater to a variety of applications, delivering clean, accurate, and durable finishes for all your industrial needs.

Whether you require standard bevels or custom profiles, our team has the expertise and tools to meet your exact specifications. Our services are ideal for industries like oil and gas, construction, and manufacturing, where precision and reliability are paramount.